product

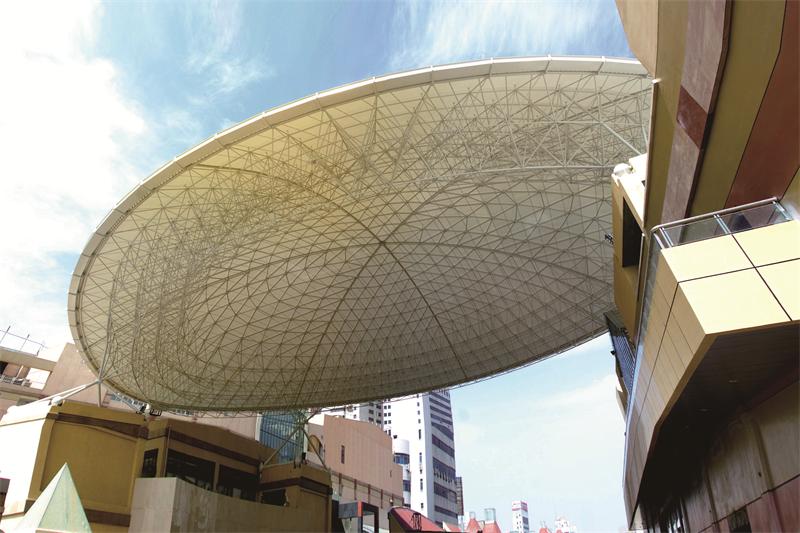

This structure is composed of membrane material, steel cables, and columns. The tension introduced into the membrane through the steel cables and columns stabilizes the structure. This form not only allows for creative, innovative, and aesthetically pleasing designs but also best expresses the essence of membrane structures. Large-span spaces often adopt a structure where steel cables and compression materials form a steel cable net that supports the upper membrane material. Due to its high construction precision, strong structural performance, and rich expressiveness, the cost is slightly higher than that of frame-supported membrane structures.

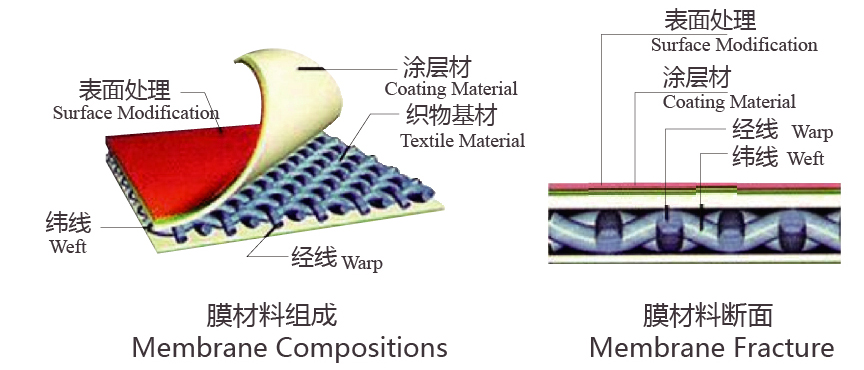

Membrane structure materials consist of two parts: the base fabric and the coating. The base fabric is primarily made of polyester fibers and fiberglass materials, while the coating materials mainly include polyvinyl chloride (PVC) and polytetrafluoroethylene (PTFE).

PTFE

PTFE membrane material is made by coating ultra-fine fiberglass fabric with polytetrafluoroethylene (PTFE) resin. The key characteristics of PTFE architectural membrane material include being lightweight, high-strength, fire-resistant, and having excellent self-cleaning properties. It is unaffected by ultraviolet light, resistant to fatigue and twisting, durable, and has a long lifespan. PTFE membranes also feature high light transmission and absorb very little heat. The invention of this revolutionary membrane material has enabled membrane structure buildings to become modern permanent architectural solutions.

PVDF

PVDF membrane material is made by coating polyvinylidene fluoride (PVDF) resin on the surface of PVC (polyester fiber) fabric. It not only addresses the issues of poor self-cleaning in PVC membranes and the migration of plasticizers to the surface that attracts dirt from air and rain, making it difficult to clean, but also significantly enhances durability. This type of membrane material was developed and applied relatively early. It has high mechanical strength, impact resistance, wear resistance, and creep resistance, along with good toughness. Additionally, PVDF has been widely used in the market, providing a cost-effective advantage due to its large production scale.

ETFE

ETFE membrane material is directly made from ethylene-tetrafluoroethylene (ETFE) copolymer raw material. Known as "soft glass," it is lightweight, weighing only 1% of glass of the same size. It has excellent toughness, high tensile strength, and is difficult to tear, with an elongation greater than 400%. ETFE also has strong weather resistance and chemical corrosion resistance, with a melting temperature as high as 200°C. It can effectively utilize natural light, saving energy, and provides good acoustic performance. The self-cleaning function prevents dirt from adhering to the surface, and rainwater can easily wash away any small amount of dirt. The cleaning cycle is approximately five years.

This structure is composed of membrane material, steel cables, and columns. The tension introduced into the membrane through the steel cables and columns stabilizes the structure. This form not only allows for creative, innovative, and aesthetically pleasing designs but also best expresses the essence of membrane structures. Large-span spaces often adopt a structure where steel cables and compression materials form a steel cable net that supports the upper membrane material. Due to its high construction precision, strong structural performance, and rich expressiveness, the cost is slightly higher than that of frame-supported membrane structures.

This structure consists of a roof framework made of steel or laminated timber, with membrane material tensioned over it.

This structure is composed of membrane material, steel cables, and columns. The tension introduced into the membrane through the steel cables and columns stabilizes the structure.

Air-supported membrane structures use high-performance membrane materials as the building’s “shell.” By creating a pressure difference between the inside and outside